Little gets in the way of entrepreneurship, not even a global pandemic. The Michael Crouch Innovation Centre's Makerspace didn’t miss a beat when COVID-19 hit quickly finding a way to remain open and continue its service of the UNSW entrepreneurial community.

A clear differentiator for the UNSW Founders program is providing startups with access to a Makerspace which empowers UNSW entrepreneurs and researchers with the opportunity to prototype and validate their ideas and products in a barrier free, ' hands on' environment.

The onset of COVID-19, and enforcement of physical distancing measures, saw the Makerspace quickly pivot from enabling founders to ‘make their own’ to a ‘click and collect’ service where startups and researchers could submit their requests for the team to process.

To provide flexibility and convenience of collection, the Makerspace then collaborated with UNSW startup, Yellowbox. Yellowbox smart lockers were installed outside the Makerspace and using the Bluetooth technology, founders were able to collect their components at their own convenience; 24/7, barrier free and totally contactless.

“We have had an enthusiastic response from the community” says Gregory Davis, Prototype Manager, MCIC Makerspace. “Since the onset of the COVID-19 restrictions we have provided well over 1,000 hours of support covering requests for a wide range of activities from 3D printing and laser cutting to scanning and vacuum forming.”

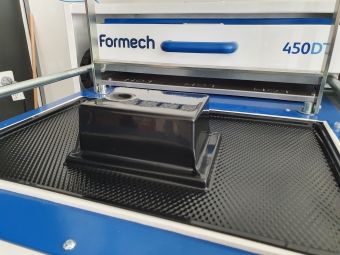

One company to take advantage of the Makerspace ‘click and collect’ service was Charopy, a Sydney based startup that works within a container deposit scheme (CDS) to eliminate recycling bin contamination in offices and other non-kerbside locations. The first to use the new Formech Vacuum former, the team created electronic housings for the Charopy smart bins.

Tiliter, an Australian technology startup providing accurate and flexible identification systems using the latest in AI, machine learning and computer vision to automatically recognise fruit and vegetables at the supermarket checkout, removing the need for manual selection and barcoding, was another business that sought help from the team. When their global supply chain was cut, they turned to the Makerspace to provide a solution to help them fulfil their client commitments.

“It’s been such a rewarding experience to continue to service our entrepreneurial clients and assist them to thrive during these challenging times.”

Hardware based startups in need of prototyping support, please contact Gregory Davis, Prototype Manager, MCIC Makerspace.